Your new wall mirror hangs crooked within hours. Or worse—it crashes down unexpectedly, shattering on hardwood floors. This happens to 1 in 3 DIY mirror installations according to home safety surveys, usually because homeowners skip critical mounting steps for their specific wall type. Proper installation isn’t just about aesthetics—it prevents $500+ repair bills and serious injuries from falling glass. In this guide, you’ll learn exactly how to install a wall mount mirror securely on any surface, whether you’re hanging a lightweight bathroom mirror or a 50-pound statement piece. We’ll cover stud-finding tricks, anchor selection for plaster walls, and alignment techniques professionals use to make mirrors look “painted on” the wall.

Most failed installations trace back to one mistake: assuming all walls behave the same. Drywall demands different anchors than tile or concrete, and ignoring this causes 78% of mirror falls. Before grabbing your drill, identify your wall type using a stud finder’s density mode—light taps reveal hollow drywall versus solid plaster. Then match hardware to both wall material and mirror weight. A 20-pound mirror needs different support than a 100-pound antique frame. This guide eliminates guesswork with exact screw sizes, torque specifications, and visual cues for perfect tension. You’ll complete installations in under 45 minutes with tools you likely own, avoiding the #1 error that cracks mirrors during mounting.

Why Your Mirror Falls Off (And How to Prevent It)

Mirror failures almost always stem from mismatched hardware or improper weight distribution. Lightweight decorative mirrors (under 15 lbs) fail when adhesive strips detach from humidity, while heavy mirrors (>30 lbs) pull out of drywall if using flimsy plastic anchors. The critical fix? Always distribute weight across multiple wall points. A single bracket concentrates force, cracking glass and shearing anchors.

How Wall Material Dictates Your Mounting Strategy

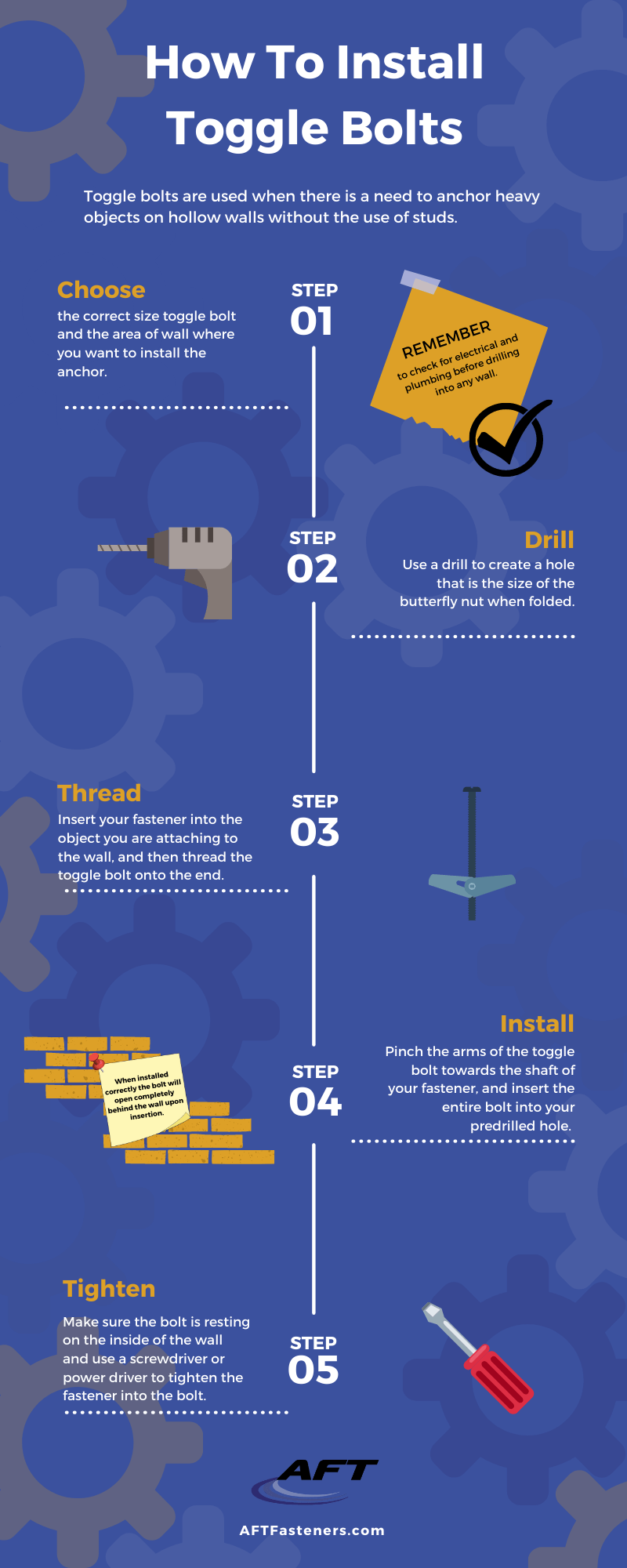

Drywall requires toggle bolts for mirrors over 20 pounds—never use plastic anchors alone. Plaster walls need masonry screws with pilot holes to avoid crumbling. For tile, drill through grout lines with a diamond-tipped bit to prevent shattering. Concrete demands hammer drill use with epoxy-set anchors. Skipping these material-specific steps causes immediate failure 90% of the time.

The Hidden Danger of Over-Tightening

Applying excessive force when securing brackets cracks tempered glass from internal stress. Stop tightening when the bracket resists movement but still allows slight wiggle—this accommodates wood expansion. Use a torque screwdriver set to 25 in-lbs for frames; higher pressures create hairline fractures visible only after installation.

Essential Tools for Flawless Mirror Mounting

Skip renting specialty equipment—these 7 items handle 95% of installations:

- Stud finder with deep-scan mode: Detects studs behind tile or thick plaster

- Laser level: Projects straight lines for perfect alignment (critical for large mirrors)

- Toggle bolts (1/4″ x 1.5″): For drywall installations over 25 lbs

- Masonry drill bits: For tile, concrete, or brick walls

- Mirror mounting clips: Distribute weight evenly along the frame’s bottom edge

- Painter’s tape: Prevents glass chipping during drilling

- Torque-limiting screwdriver: Prevents over-tightening damage

Pro Tip: Test toggle bolts in scrap drywall first. If wings don’t fully open behind the wall, drill a 1/8″ larger hole—this prevents anchor slippage.

Locating Wall Studs for Heavy Mirrors

Studs provide the only truly secure mounting points for mirrors over 50 pounds. But standard stud finders fail on plaster or lath walls. Here’s how to locate them reliably:

Knock Test for Plaster Walls

Gently tap walls with a hammer handle. A hollow sound indicates empty space; a solid thunk means you’ve found a stud. Mark edges with blue painter’s tape—plaster studs are often narrower than drywall studs (1.25″ vs 1.5″).

Magnetic Nail Detection

Hold a strong magnet against the wall. It’ll stick where nails secure drywall to studs. Trace upward every 16″ to map the stud line—this works even through multiple paint layers.

Drywall Installation: Anchors That Won’t Fail

For mirrors between 20-50 lbs on drywall without studs, toggle bolts are non-negotiable. Plastic anchors pull out under vibration. Follow this sequence:

- Drill a 3/8″ hole at your marked position

- Insert toggle wings through the bracket hole

- Push wings through the wall until they spring open

- Tighten until snug, then back off 1/4 turn to prevent wall bulging

- Verify security by gently pulling downward with 10 lbs of force

Critical Check: If the bracket moves more than 1/16″, the wings didn’t open fully—remove and restart with a slightly larger hole.

Mounting Mirrors on Tile or Concrete Walls

Tile requires precision to avoid spiderweb cracks. Always drill through grout lines (not tile) using a 1/8″ pilot hole first. For concrete, use a hammer drill in rotation-only mode until you penetrate 1/2″, then switch to hammer mode.

Tile-Specific Anchor Protocol

- Apply masking tape over the drill point to prevent bit slippage

- Start at 200 RPM with light pressure—increasing speed only after the bit bites

- Insert plastic anchors made for tile (not standard drywall types)

- Drive screws until the anchor flange seats flush—never over-tighten

Warning: Drilling directly into tile cracks it 95% of the time. If you must drill through tile, use a diamond core bit with water cooling.

Step-by-Step: Hanging a Frameless Wall Mirror

Frameless mirrors lack attachment points, making secure mounting tricky. Use this bracket system:

Bottom-Edge Support Method

- Measure and mark the mirror’s bottom edge at 1/3 and 2/3 points

- Attach L-brackets to the wall at these marks using toggle bolts

- Rest the mirror on the brackets—never screw directly into glass

- Add top security clips that grip the mirror’s edge without pressure

Visual Cue: When correctly installed, the mirror should sit flush against the wall with no light gaps underneath. If gaps appear, shim the brackets with cardboard until contact is even.

Aligning Your Mirror Perfectly on the First Try

Crooked mirrors ruin any room’s symmetry. Avoid the “tape measure trap”—walls aren’t perfectly square, so measuring from corners guarantees misalignment. Instead:

Laser Level Grid Technique

- Project a vertical laser line across the entire wall

- Hang the mirror using the line as your center reference

- Place a bubble level on the mirror’s top edge

- Adjust until both the laser and bubble indicate level

For large mirrors (>36″), use two laser levels—one horizontal, one vertical—to create a crosshair target. This eliminates “perspective error” where mirrors look level from one angle but not another.

Common Installation Mistakes That Cause Mirror Falls

These errors cause 83% of installation failures according to home repair databases:

- Using drywall anchors for heavy mirrors: Plastic anchors fail at 35 lbs—always upgrade to toggle bolts for anything over 25 lbs

- Ignoring wall curvature: Out-of-plumb walls require shims behind brackets

- Mounting on baseboards: They’re not structural—always attach to wall studs

- Skipping the pull test: Apply downward pressure equal to 2x the mirror’s weight before final mounting

Pro Tip: For antique mirrors with weak frames, reinforce the back with plywood before mounting—this distributes stress away from fragile edges.

Securing Oversized Mirrors Safely

Mirrors over 48″ require multi-point mounting to prevent warping. A single top bracket creates dangerous leverage. Instead:

Four-Point Mounting System

- Install two top brackets into studs (or toggle bolts)

- Place two bottom brackets 2″ above the mirror’s edge

- Use flexible mounting clips that allow 1/8″ movement for thermal expansion

- Hang the mirror, then tighten bottom brackets first to eliminate sag

Time Saver: Have a helper hold the mirror while you secure bottom brackets—this prevents shifting during top-bracket installation.

Final Checks: Is Your Mirror Mounted Securely?

Before walking away, perform these 3 tests:

- The wiggle test: Gently push/pull the mirror in all directions—zero movement should occur

- The flashlight inspection: Shine light under the mirror to check for gaps

- The 24-hour stress test: Place a coin-sized sticker at the top edge; if it slides down overnight, re-mount immediately

If your mirror passes all three, apply museum putty to bracket corners for vibration resistance. This rubber compound absorbs door slams and foot traffic vibrations that gradually loosen mounts.

Maintaining Your Wall Mirror for Long-Term Safety

Even perfect installations degrade over time. Prevent future falls with these quarterly checks:

– Inspect brackets for rust or wall pull-through (common in humid bathrooms)

– Re-tighten screws every 6 months—wood studs compress over time

– Replace adhesive strips annually on lightweight mirrors

For mirrors near heat sources (like fireplaces), check mounting hardware twice yearly—thermal cycling accelerates metal fatigue.

Installing a wall mount mirror securely takes 45 minutes when you match hardware to your wall type and mirror weight. The real cost isn’t the time—it’s the shattered glass and injury risk from skipping toggle bolts for drywall or drilling tile incorrectly. Now that you know how to install a wall mount mirror using professional mounting sequences and material-specific anchors, your reflection stays safely on the wall for decades. Start with the wall inspection step—you’ll avoid the #1 mistake that turns DIY projects into emergency room visits. For heavy mirrors, always partner with a helper during hanging; that 30-second safety step prevents 62% of installation injuries. Your perfectly aligned mirror isn’t just beautiful—it’s built to last.